Hot air → high pressure → mechanical motion

ideal:

Pressure (lbs/in^2) *dV(in^3) = Work (lbs*in)

actual

PdV = frictional losses, entropy, heat loss, + a little bit of work...

Review:

http://www.grc.nasa.gov/WWW/k-12/airplane/engparts.html

Vocab:

Engine - System used to produce a net power output

Mechanical cycle - a sequence of processes that begin and end at the same state.

Gas cycle - working fluid remains a gas through the entire cycle.

Vapor cycle - fluid alternates between liquid and vapor through the cycle

Closed and open cycles:

Closed cycles -

.

.

.

Open cycle - fluid comes in, gets used up, then exhausts out, the working fluid does not go through a complete thermodynamic cycle.

External combustion engine: Steam power plant, energy is supplied from an external source, such as a furnace, geothermal well, nuclear reactor, the sun, etc.

Internal combustion engine: Fuel is burned inside of the system.

Analysis of Power Cycles:

Start with an Ideal Cycle

Assume ideal reversible process, ignore friction, assume system is in thermodynamic equilibrium, ignore unwanted heat loss to surroundings.

Reversible process: adiabatic (no heat loss out of system), you can go back and forth between state 1 and state 2 either in forward or in reverse, the path does not matter.

Idealized model - study major parameters without being bogged down with details.

Trends in ideal cycles match trends in actual cycles, but #'s in ideal cycles do not match #'s in actual cycles

Ideal assumptions:

No friction between moving parts

Quasi-equilibrium expansion and compression processes

Negligible heat transfer in connecting parts.

4 strokes:

https://www.grc.nasa.gov/www/k-12/airplane/work2.html

Work = area inside the P-v loop

Carnot - most efficient ideal cycle

isothermal = constant T

Adiabatic = no heat transfer/loss, perfectly insulated walls.

https://www.grc.nasa.gov/www/k-12/airplane/carnot.html

http://en.wikipedia.org/wiki/Carnot_heat_engine

The area enclosed by the cycle on a p-V diagram is proportional to the work produced by the cycle.

What do these ideal cycles teach us?

Thermal efficiency (gas mileage) increases with compression ratio.

Compression ratio - CR

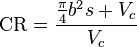

, where

, where = cylinder bore (diameter)

= cylinder bore (diameter) = piston stroke length

= piston stroke length = clearance volume - the

volume of the combustion chamber (including head gasket). This is the

minimum volume of the space at the end of the compression stroke, i.e.

when the piston reaches top dead center (TDC). Because of the complex

shape of this space, it is usually measured directly rather than

calculated.

= clearance volume - the

volume of the combustion chamber (including head gasket). This is the

minimum volume of the space at the end of the compression stroke, i.e.

when the piston reaches top dead center (TDC). Because of the complex

shape of this space, it is usually measured directly rather than

calculated.

Diesel engines - better compression ratios, Why?

Consider fire pistons:

Diesel engine - no spark plug, direct fuel injection, fuel ignites through compression.

Fuel injected after air is compressed so no worries on compression ratios = better fuel economy. (Trick is injecting fuel to mix homogeneously with air)

Gasoline engine - carburetor mixes air and fuel, then fuel is ignited by spark plug. (If it ignites on it's own, the timing will be off, and you get engine knock, so there's an upper limit to the compression ratio you can use.)

Higher octane fuels - combustion at higher temp - increased compression ratios.

Gasoline - C9H20

Diesel - C14H30 - longer chain, heavier more oily fuel, less refined so cheaper to make, evaporates more slowly than gas, higher energy density, greater MPG,... pollutes more than gas.

http://www.animatedengines.com/otto.html

Internal Engine Project:

Start with a piston & Connecting rod

Read through this:

http://confident-instruments.com/Piston_Study.htm

Piston:

http://en.wikipedia.org/wiki/Piston

Piston Rings:

http://en.wikipedia.org/wiki/Piston_ring

Wrist Pin:

http://en.wikipedia.org/wiki/Wrist_pin

Connecting Rod:

http://en.wikipedia.org/wiki/Connecting_rod

Crank Shaft:

http://en.wikipedia.org/wiki/Crankshaft

Cam Shaft:

http://en.wikipedia.org/wiki/Camshaft

Choose your materials, and include tolerances in your views.

Piston Schematics:

F...... Top land height

GL..... Total length

KH..... Compression height

MO..... Combustion chamber diameter

MT..... Combustion chamber depth

MV..... Combustion chamber offset

UH..... Dome height

VT..... Valve recess depth

Do a Google image search, choose a make/model, dimension everything out!

Read through:

http://courses.washington.edu/engr100/Section_Wei/engine/UofWindsorManual/Piston%20and%20Piston%20Rings.htm

http://courses.washington.edu/engr100/Section_Wei/engine/UofWindsorManual/Piston%20Design.htm