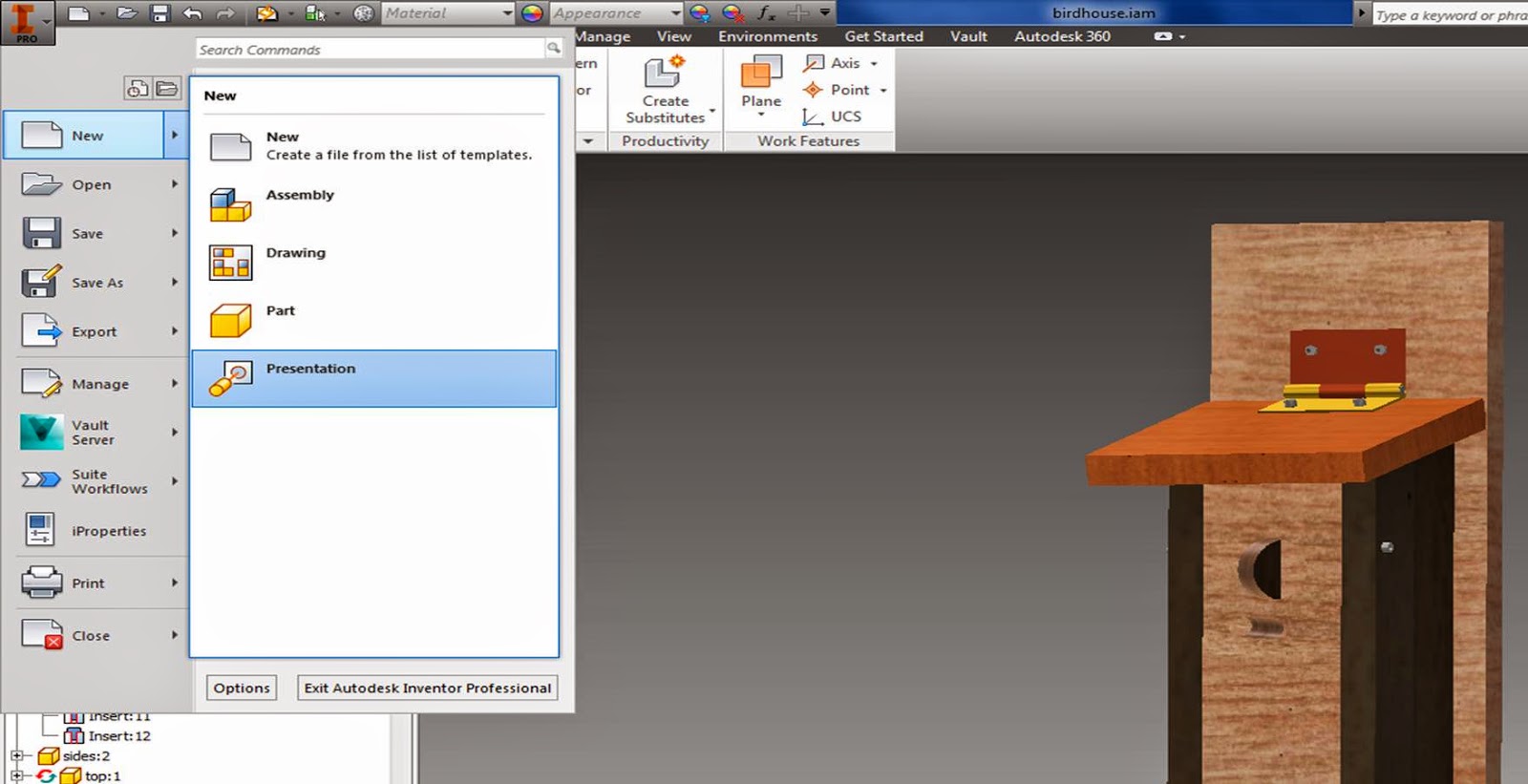

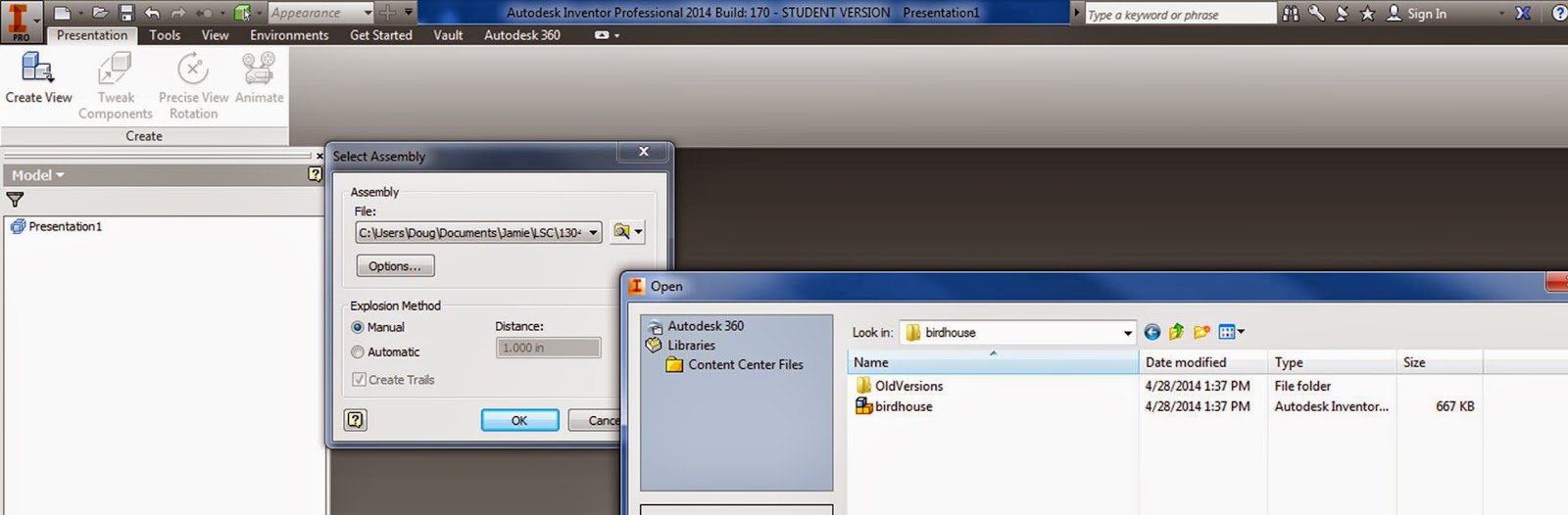

New→Presentation

Options → just leave as default

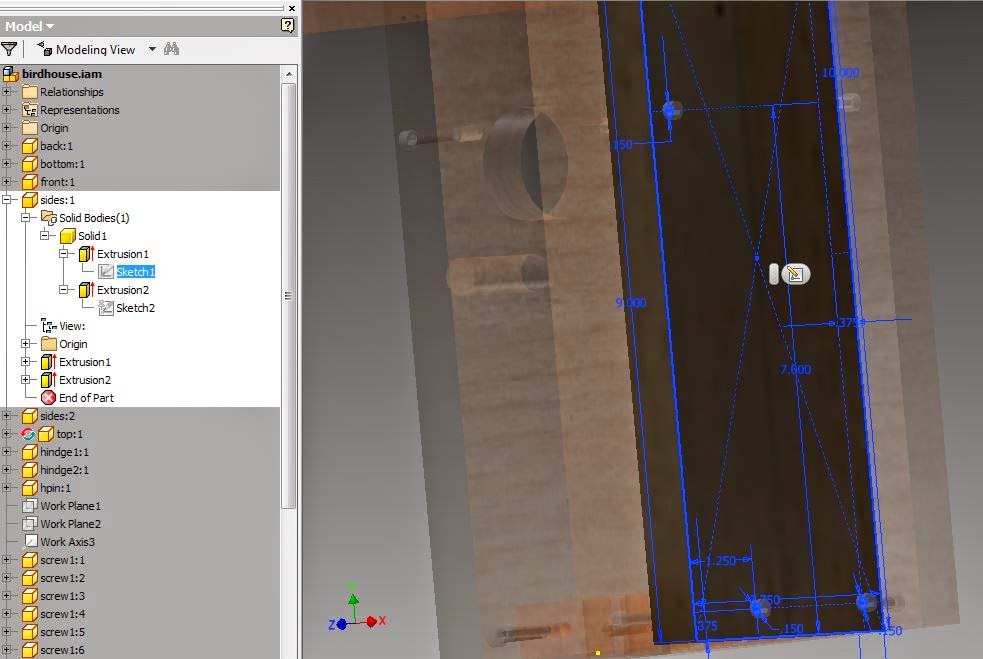

Make sure your browser is selected under view→User interface

Expand the parts in your browser,

right click to turn the visibility on and off

Right click on the corner of your ViewCube to change to perspective / Ortho views

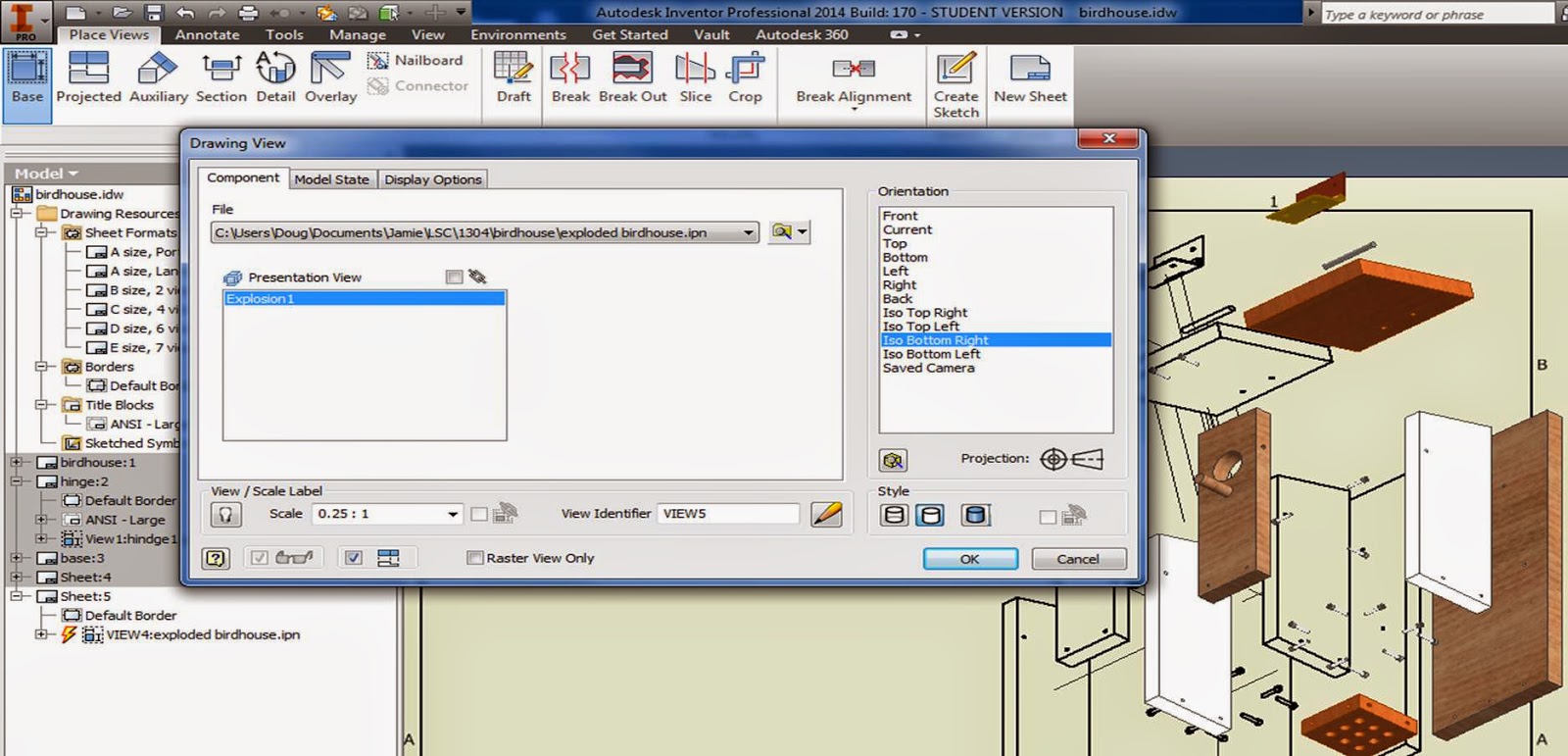

Position your assembly with a nice orientation

Click on New Snapshot View

Right click on view to rename, make a jpg, etc.

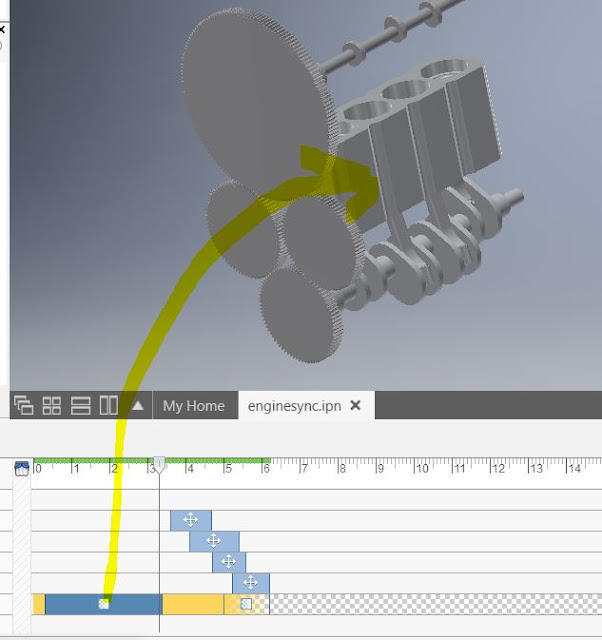

Pull the slider on the storyboard to some time (4 seconds) to start creating a movie

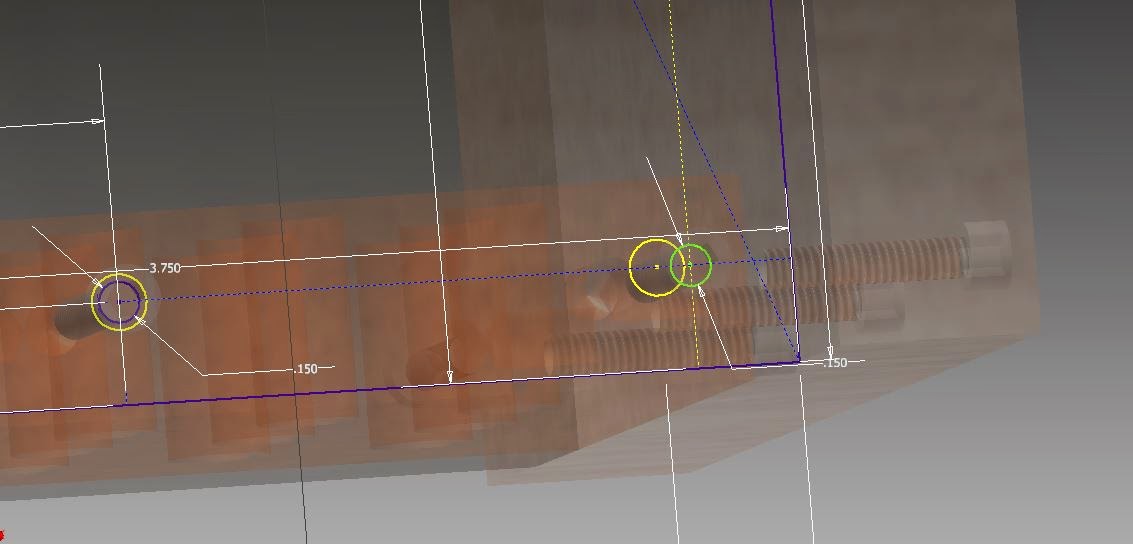

Tweak components→click on a gear or other piece of your assembly→pull it away

We'll explode all of the parts from one another to show the individual components and the assembly

Set the time that each motion will take, decide if you want a trail or not,

move a few of your components around

Click "OK",

Play your movie so far!

Drag the slider to watch the motion of the components

Pull the lower menu edge to expand

Expand tweaks in the model tree

right click to edit tweaks

drag tweaks in storyboard to change timing

Click on your engine block, and try out the Opacity tool!

Try out capture camera -

rotate assembly to a new view

click on capture camera

adjust timing in the story board

Once you have all of your components pulled apart and your video how you want it, click on the video tool, and save your movie!

Once you are finished with your movie - work on your project!

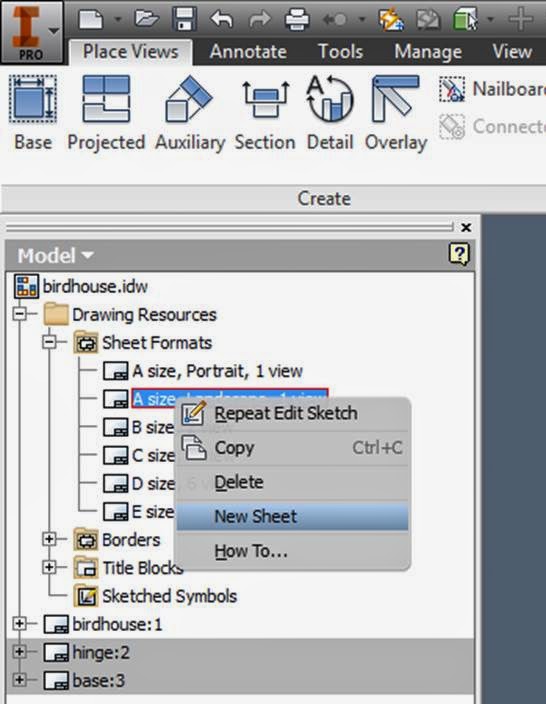

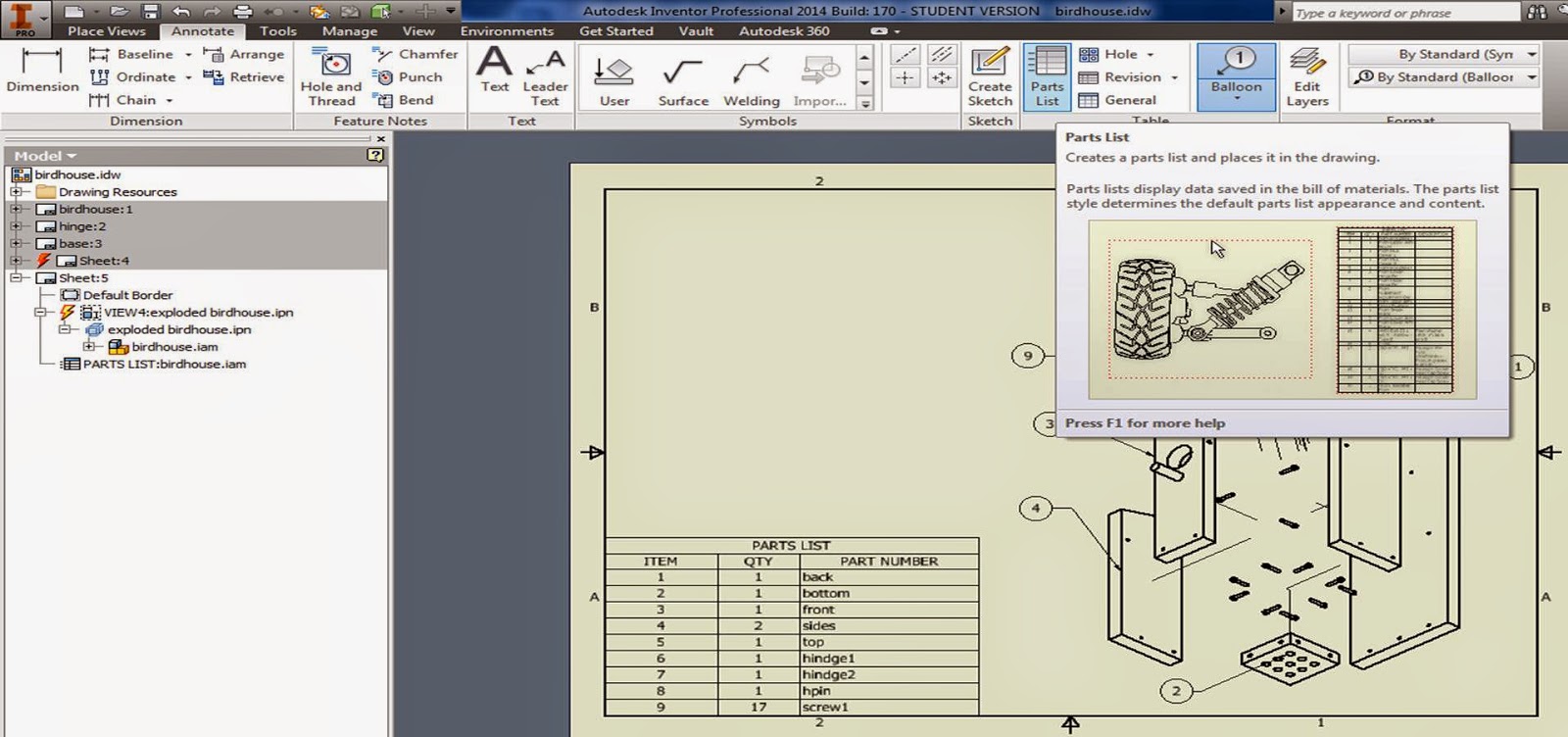

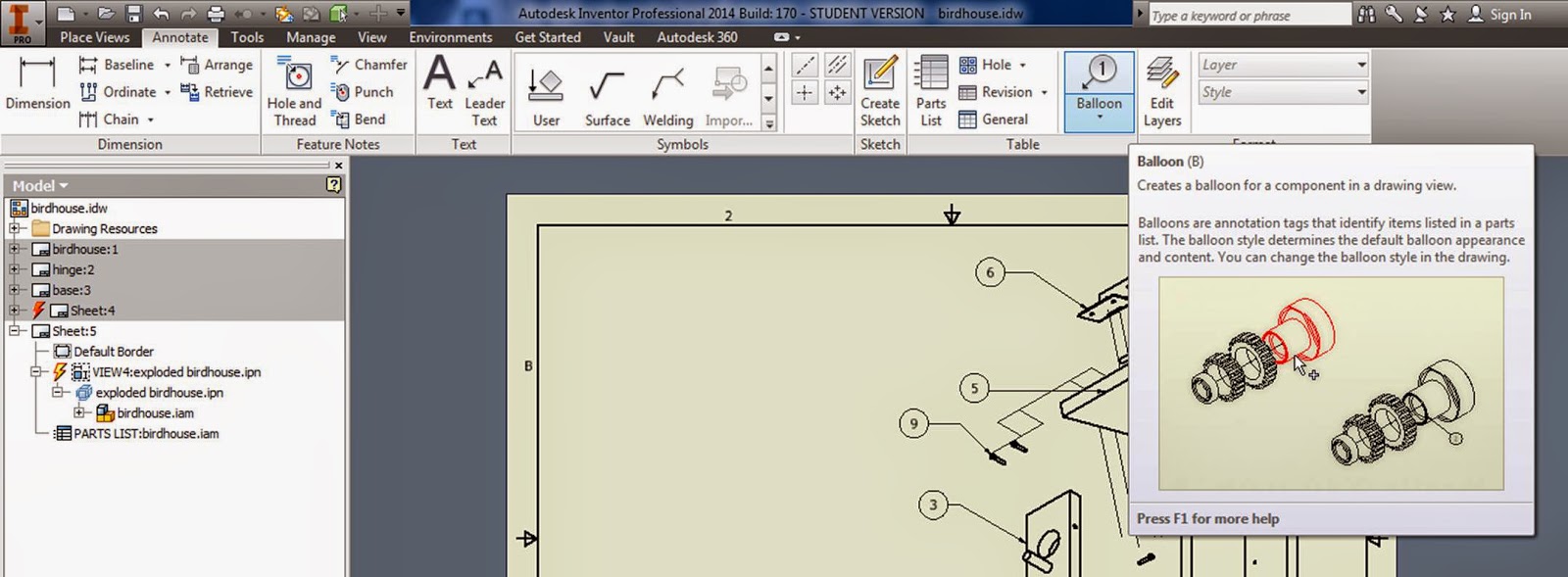

Next class - creating a set of working drawings with dimensions, parts lists, etc.

additional notes:

https://designandmotion.net/autodesk/inventor/inventor-2017-presentations/