Eighty to eighty-five percent of all automobile recalls are fastener related."

- Joseph R. Dudley, V.P. Automotive Marketing, Nylok Fastener Corp. May 1995

http://www.space.com/11745-loose-bolts-space-station-spacewalkers-trouble.html

Fastening:

Two or more components that are joined. Do not require orthographic views, just the info to purchase the part.

Permanent Fasteners:

adhesives, welds, braces, solders, rivets, nails.

Non-Permanent Fasteners:

Screws, bolts, nuts, pins

Notes: http://www.gizmology.net/nutsbolts.htm

https://www.fastenal.com/web/en/78/screw-thread-design

Thread Characteristics:

Direction

Most are right handed (righty tighty, lefty loosy)

Left handed threads - used where right handed threads would become loose in the application (lawn mower blades)

Lead

Distance traveled during one revolution of the fastener.

Lead = Pitch for single threaded screws.

Double and triple threaded bolts - one revoltuon = 2 or 3 times the pitch.

Double and triple threading give rapid motion + large thread surface.

Form

Cross-sectional shape, profile.

N - Rounded V profile (rounded for ease of manufacturing)

ACME - Heavy loads, high accuracy

BUTTRESS - High axial loads

SQ - hard to manufacture

Series

Number of threads per inch for a specific diameter.

coarse - general purpose used for holding

fine - to support added force, used in aircraft and automotive industries

extra fine - for short and small diameter fasteners.

Thread spec's:

3 standard representations:

Loose fit (1) for harsh corrosive environments.

Regular and Average fits (2) General purpose

Tight (3) For high pressures, stresses, and vibrating systems.

Thread Notes:

Notes on drawing that provide specs about thread.

Use a "leader" to connect note to thread

English Thread:

←0.375-32UNEF-3A-LH

0.375 = diameter

32 = threads per inch

UN = Form

EF = Extra fine (could be C for coarse, or F for fine)

3 = class of fit (1 = loose, 2 = regular, 3 = tight)

A = external thread (B = internal)

LH = left handed

Above: Diameter = .25", 28 threads per inch, United National, Fine series, average fit, external, right handed. (LH would be left handed, nothing written assumes right handed)

Thread Table:

1st column - diameter

(a coarse threaded 1.25" diameter bolt has 7 threads per inch)

Metric:

only listed as coarse or fine.

M - metric

90 - thread diameter

X

6 - pitch (in mm)

Metric threads are usually defined by their pitch, that is,

how much distance per thread, inch-based standards usually use the reverse

logic, that is, how many threads occur per a given distance. Lead is the

distance along the screw's axis that is covered by one complete rotation of the

screw (360°). Pitch is the distance from the crest of one thread to the next.

Because the vast majority of screw thread forms are single-start thread forms,

their lead and pitch are the same.

Tolerance class: 3, 4, 5, 6, 7, 8, 9 + E, G, H.

#3-9 = tolerance grade (larger num = larger tolerance)

#3-9 = tolerance grade (larger num = larger tolerance)

6 = medium = most common

Letter = type of fit:

E = loose

G = regular

E = loose

G = regular

H = tight

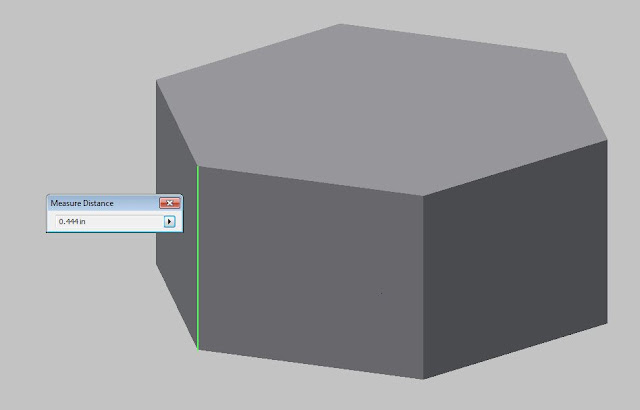

Head:

Work through all of your Chapter 8 WS's!

Experiment with making your own threaded fastener - look through all of Inventor's different thread types etc.

Try out Manage → Parameters. This is where you can keep track of your dimensions, and even name dimensions to use them later on.

Right lick on dimension → Dimension Properties → you can show your parameter dimensions

older version:

Revolve around the center axis (Y Axis in my case)

Try making some of the fasteners out of chapter 8!